|

HYDROCARBON RESIN (PETROLEUM RESIN)

Hydrocarbon Resin for Hot Melt Road Marking Paint Introduction:

They have excellent comatibility with EVA, APAO, styrene block polymers(such as SIS SBS SEBS),

Natural Rubber and many kinds of synthetic rubbers, as well as natural tackifier resins(such as terpene,

colphony and its derivatives).They provide enhanced performance in Hot Melt Adhesive applications.

|

|

|

Specification:

| properties/Types |

AHHR-90 |

AHHR-100 |

AHHR-101 |

AHHR-110 |

AHHR-120 |

Test methods |

| Appearance |

Granule |

Granule |

Granule |

Granule |

Granule |

Eyeballing |

| Color No.(Ga.) |

≤6 |

≤6 |

≤6 |

≤6 |

≤6 |

ASTM D-1544 |

| Softening point(C) |

95±5 |

100±5 |

105±5 |

110±5 |

120±5 |

GB/T4507 (Ring and Ball) |

| Acid Value (mgKOH/g) |

≤1 |

≤1 |

≤1 |

≤1 |

≤1 |

GB2895 |

| Heat Resistance (200˚C 3h)Ga. |

≤8.5 |

≤8.5 |

≤8.5 |

≤8.5 |

≤8.5 |

ASTM D-1544 |

| Melt Viscosity (200°C )cps. |

Test if need |

ASTM D-3236 |

| Flash Point(°C) |

Test if need |

GB261/GB3536 |

| Insoluble Voll% |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

|

Application:

AHHR-9OAHHR-100AHHR-1O1AHHR-110 and AHHR-120 are suitable for Hot Melt Adhesives, including quick packaging

adhesives, bookbinding adhesives, adhesive, adhesive tape and glue sticks. They also can be used singly as tackifier resin in Hot Melt

Adhesive, and can also be used in blends with different resins to improve adhesive performance.

Package:

Packed in 25kgs paper bag 16MT without pallets or 14MT with pallets for 1*20 FCL.

Storage & Defence:

They are non-hazardous product, It should be stored in dry and cool place with fire fighting facilities.

Far away from fire, sunshine,moist and pollution.

|

|

Hydrocarbon Resin for Hot Melt Road Marking Paint Introduction:

AD5100AD51O1AD5110AD5111 are special resins for holt melt road marking paints, which can enhance the tenacity,rigidity

and adhesive force of dope and form smooth paint surface. Also they can ensure the stable state of the resin in the four seasons by

adding auxiliary agent and it have a better mixing with rosin. For top-grade paint,it can form such features as water-proof, antiultraviolet

radiation, anti-chemicals, and improve the brightness and dryness of the surface.

Specification:

| Properties/Types |

AD5100 |

AD5101 |

AD5110 |

AD5111 |

Test methods |

| Appearance |

Granule |

Granule |

Granule |

Granule |

Eyeballing |

| Softening point(˚C) |

100±4 |

100±4 |

100±4 |

100±4 |

GB/T4507 (Ring & Ball) |

| Color No.(Ga.) |

≤5 |

≤6 |

≤5 |

≤6 |

ASTM D-1544 |

| Acid Value (mgKOH/g) |

≤4 |

≤4 |

≤4 |

≤4 |

GB2895 |

| Melt Viscosity(200°C )cps |

≤250 |

≤250 |

≤250 |

≤250 |

ASTM D-3236 |

| Heat Resistance (200°C 3h)Ga. |

≤8 |

≤8 |

≤8 |

≤8 |

ASTMD-1544 |

| Flash Point°C |

Testing by users demand |

GB261 /GB3536 |

| Solubility in Benzene |

Clear |

|

| Bromine Value(gBr/100g) |

Testing by users demand |

|

Package:

Packed in 25kgs paper bag,pp bag or paper and pp compounding bags;16MT without pallets or 14MT with pallets for 1*20 FCL.

Storage & Defence:

Non-hazardous.lt should be stored in dry and cool place with fire fighting facilities. Far away from fire, sunshine,moist and pollution.

|

|

|

CHLORINATED POLYPROPYLENE (CPP RESIN)

Product features:

1. White or yellowish granular powder of polypropylene derivatives, containing Cl

groups in its chemical structures.

Testing by users demand Produced through an environmentally friendly method of solvent processing, which is

ground breaking in China. The quality of the product can rival that of the imported.

3. Non-toxic, tasteless, no solvent residue, fast dissolving, good filming, and high level

of adhesion.

|

|

|

Specification:

| Item |

Indicators |

|

|

|

HM-A |

HM-B |

HM-C |

| Appearance |

White of yellowish granular powder |

| Chloride content % |

30-33 |

| Viscosity(mPa.s) |

180-260 |

260-340 |

340-420 |

| Solubility % |

≥98 |

| Moisture |

≥0.5 |

Usage:

1. Major resina of the printing ink for intaglio printing with BOPP-film (Bi-axially Oriented Polypropylene).

2. Coating for BOPP film and adhesive for the double-layered PP film pp film-paper, etc. in Packaging Industry.

3. Adhesive for coatings on polypropylene profiles.

Packing, storage and transportation:

1. In polypropylene woven bags with polyethylene inner bag. Net weight: 20kg/bag.

2. Be stored up in cool, dark and dry storehouses. Mind the high temperature and rain when being transported.

|

|

|

CHLORINATED ETHYLENE

VINYL ACETATE COPOLYMER (CEVA)

Property:

CEVA is soluble in toluene and xylene. It has elasticity like rubber, good solubility and fluidity at room temperature. In addition,it has

good weather resistance, chemical resistance, oil resistance, ozone resistance and flame resistance property.

Usage:

CEVA is mainly used to produce wear resistant, heavy corrosion resistant and self-extinguishing coatings, high-grade adhesives, high

quality printing ink and high-grade plasticizer of PVC films.

1. Coatings: widely used in ship coatings, road marking coatings, swimming pool paintings, chemical equipment and decorating

painting of wood and cement.

2. Adhesives: widely used in paintings and coatings, Especially in compound painting, it can improve the adhesive property of the

painting to plastic films and therefore the quality of the patterns is improved.

3. Others: CEVA can be used to produce tube, insulation of cables and wires and shoes.

Specification:

| Items |

CEVA |

| Appearance |

milk white blocky solid |

| Content of chloride(%)≥ |

18-22 |

| Viscosity(mpa.S) |

300-400 |

| PH |

4.5-6.5 |

Note: 1. viscosity is measured in 20% toluene solution at 25+/-1°C by rotational viscometer

2. rotational viscometer is at 750 r.p.m.

|

|

|

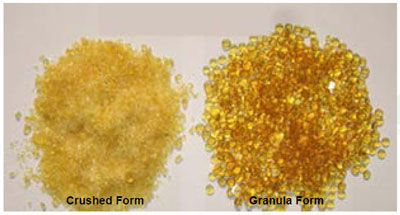

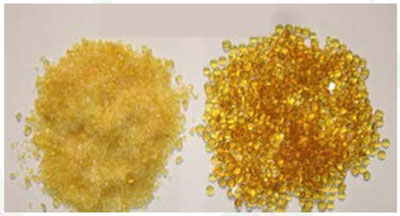

POLYAMIDE RESIN BENZENE SOLUBLE

Type: HM-1014(Co-solvent type)

The product is a kind of economical and practical benzene soluble polyamide resin, which is developed accommodating to the market requirement.

It has good stability, good solvent liberation, strong bending flexure, marvelous glossiness, strong adhesive power, fine gel resistance and indoor

temperature turn-frost, widely used in various printing fields.

Apperance:

Light yellow crushed form and crushed form

Uses:

***Plastic intaglio printing ***Plastic flexibility issue printing

***Heating seal beaded paint ***Cover glass oil

Typical index:

| Color(40% resin soluble in the component solvent of dimethylbenzene: isopropyl alcohol:absolute alcohol:4:3:3) |

8max |

| Amine Value mgkoH/g Acid value mgkoH/g |

4max |

| Acid value mgkoH/g |

5max |

| Viscosity(40% resin soluble in the component solvent of dimethylbenzene: isopropyl alcohol:absolute alcohol:4:3:3) |

100-l4Ocp/25˚C |

| Softening point(ball and ring method) |

105-l18˚C |

Package, storage and transportation:

High quality triad paper bag, 25kg/bag. l5mts/1x20'FCL without pallet. Keep away from moisture and high temperature, generally stored in

shady and cool, drying and draught place; strictly forbid high temperature, sun exposure and drench during transportation.

The quality is similar to Sunmide's 550

|

|

POLYAMIDE RESIN BENZENE SOLUBLE

Type: HM-1417(Co-solvent type)

The product is a kind of economical and practical benzene soluble polyamide resin, which is developed accommodating to the market requirement.

It has good stability, good solvent liberation,strong bending flexure, marvelous glossiness, strong adhesive power, fine gel resistance and indoor

temperature turn-frost, widely used in various printing fields.

Apperance:

Light yellow crushed form and crushed form

Uses:

| Plastic intaglio printing |

|

Plastic flexibility issue printing |

| Heating seal beaded paint |

|

Cover glass oil |

Typical index:

| Color(40% resin soluble in the component solvent of dimethylbenzene: isopropyl alcohol:absolute alcohol:4:3:3) |

8max |

| Amine Value mgkoH/g |

4max |

| Acid value mgkoH/g |

5max |

| Viscosity(40% resin soluble in the component solvent of dimethylbenzene: isopropyl alcohol:absolute alcohol:4:3:3) |

140-17Ocp/25˚C |

| Softening point(ball and ring method) |

105-118˚C |

Package, storage and transportation:

High quality triad paper bag, 25kg/bag. l5mts/1x20'FCL without pallet. Keep away from moisture and high temperature, generally stored in

shady and cool, drying and draught place; strictly forbid high temperature, sun exposure and drench during transportation.

The quality is similar to Sunmide's 550H-6

|

|

|

POLYAMIDE RESIN ALCOHOL SOLUBLE

Type: HM-960(Alcohol type)

HM-960 is a kind of alcohol soluble polyamide resin, which has marvelous solvent liberation, super glossiness, pigment wettability, good

adhesive power for most process film and metallic membrane, strong bending flexure, marvelous glossiness and strong fine gel resistant and

indoor temperature turn-frost, widely used in various printing fields. Otherwise, the resin has high oxidation resistance, adhesion resistance

quality and cold resisting property, widely used for printing ink.

|

Apperance:

Light yellow crushed form and crushed form

Uses:

| ***Flexibility printing ink |

|

***Plate printing ink |

| ***Heating seal beaded paint |

|

***Cover glass oil |

|

|

|

Typical index:

| Color(50% resin soluble in the solution of 95% alcohol) |

9max |

| Amine Value mgkoH/g |

4max |

| Acid value mgkoH/g |

5max |

| Viscosity(50% resin soluble in the solution of 95% alcohol) |

120-170cp/25˚C |

| Softening point(ball and ring method) |

115-125˚C |

Package, storage and transportation:

High quality triad paper bag, 25kg/bag. l5mts/1x20'FCL without pallet.

Keep away from moisture and high temperature, generally stored in shady and cool, drying and draught place; strictly forbid high temperature,

sun exposure and drench during transportation.

The quality is similar to Sunmide's 615A

|

|

|

POLYAMIDE RESIN ALCOHOL SOLUBLE

Type: HM-010A for deep-freezing resistance ink

HM-O1OA is known for being alcohol dilutable with an improved gel resistance. Its main benefits are its outstanding adhesion and water

resistance, high gloss ad excellent water and ice crinkle resistance.

|

Apperance:

Light yellow crushed form and crushed form

Uses:

| ***Flexibility printing ink |

***Gravure ink |

| ***Deepfreezing resistance ink |

|

Typical index:

| Color(50% resin soluble in the solution of 95% alcohol) |

8max |

| Amine Value mgkoH/g |

3max |

| Acid value mgkoH/g |

6max |

| Viscosity(50% resin soluble in the solution of 95% alcohol) |

80-15Ocp/25˚C |

| Softening point(ball and ring method) |

102-1O8˚C |

|

|

Package, storage and transportation:

High quality triad paper bag, 25kg/bag. l5mts/1x20'FCL without pallet.

Keep away from moisture and high temperature, generally stored in shady and cool, drying and draught place; strictly forbid high temperature,

sun exposure and drench during transportation.

The quality is similar to Sunmide's 640 |

|

|

VINYL CHLORIDE - VINYL ISOBUTYL ETHER COPOLYMER

MP SERIES CHLORINATED RESINS

(Equivalent of BASF Laroflex ® MP Chlorinated Resins)

CAS NO.: 25154-8-2

Appearance: white thermoplastic powder, inodorous, no toxin;

|

|

|

Brief introduction:

MP serial chlorinated resins are copolymers of vinyl chloride and vinyl isobutyl ether. They can be used as base resin for air-drying paints

or other physical drying paints. At present, only Germany, USA, Japan and China can produce these items. According to the international

convention, chlorinated rubbers were forbidden to produce from 2004. MP series chlorinated resins, as base resin for heavy duty anticorrosion

paints, can replace chlorinated rubber. They have broad prospects with their high "ratio of quality to price" and environmental protection

advantage.

Application:

They are a good type of chlorinated binder Can be used for anti-corrosive paints; printing inks, steel structure paints, wall paint, road-marking

paints, buildings anti-fire paint, light metal coating, deck paints, watercraft & container paints, engineering paints for machine & automobile,

concrete & asbestos cement, etc. They can be used as modifier in rubber & plastic industry as well.

CMP45 is especially good for making solvent type gravure ink & plastic composite ink (OPP & PE).

CMP25 & 35 is especially good for anticorrosion paint (Container, marine & industrial paint). CMP-60 is especially good for special ink or

metal adhesive.

Technical data:

| Item |

Viscosity (mPa.s) |

Method |

| CMP15 |

15±3 |

Refer to 20% solution in toluene

and measurements at 23˚C

(ISO3219) in a revolving

viscometer ST VIII |

| CMP25 |

25±4 |

| CMP35 |

35±5 |

| CMP45 |

45±8 |

| CMP60 |

60±10 |

23, 20% solution in toluene, STVII |

General properties:

| K-value |

Ca.35; |

Fikentscher, DIN 53726 |

| Chlorine mass fraction |

Ca.44 |

% |

| Moisture Content |

1 |

% max |

| Apparent density |

0.45 |

g/cm3 |

Packing:

In 25kg bags craft paper bag; about 12MTS/1x20'FCL with pallet

|

|

|

VINYL CHLORIDE & VINYL ACETATE

COPOLYMER RESIN AH-VYHH

Equivalent:

VYHH" ex Union Carbon

Property:

It is vinyl chloride & vinyl acetate copolymer. It's high molecular resin (Molecular weight 27000). It provides perfect equipoise of chemical

resistance, solubility, coating strength & thermoplasticity etc. It is soluble in correspondingly strong solvent & thinner composition, for example,

50% ketone 50% aromatic hydrocarbon.

Application:

AH-VYHH used for vessel & repair paint, plastic paint, vinyl base ink & polish oil, metal / can paint & adhesive, strippable paint, magnetic

card adhesive, PU color paste & color chips, calcium PVC floor, microgroove record, etc. It has good adhesive power with paper, acrylic resin,

PVC, ABS & PC. It is complying with the standard of food & medical contact.

|

Specification:

Appearance: white powder

composition: 86% vinyl chloride + 14% vinyl acetate

K Value (VN): 54 ± 2

Fineness (passing 4omesh): 100%

Apparent density: 0.45 — 0.5

Volatile matter: 1% max

Black point: 10 numbers/ 100g max

Solubility (in 20% methyl ethyl ketone toluene solution): colorless & transparent

Packing:

25kg per craft paper bag.

Storage & transportation:

Store in dry & ventilated warehouse. Don't store it in open air. Prevent sunshine & moisture.

Avoid rain during transportation. It is not dangerous cargo. |

|

|

CARBOXYL MODIFIED TERNARY COPOLYMER AH-VMCH

Equivalent: "VMCH" ex Union Carbon

Property:

It is carboxyl modified ternary copolymer of vinyl chloride, vinyl Acetate ester & maleic acid. It's high molecular resin. Molecular weight: 27000.

It is soluble in correspondingly strong solvent & thinner composition, for example, 50% ketone 50% aromatic hydrocarbon, produce 25 — 28%

(solid count) resin solution. As there is carboxyl "-COOH" in its molecule, VAMA has perfect adhesion power with the surface of metal, paper,

carpentry, treated PE, PP, PET & PVC. It has very good chemical resistance, can resist acid, alkali, oil under normal temperature.

Application:

AH-VMCH used for air-dry finishing paint, for example, repair paint, vessel paint, metal / can / beer paint, wood & glass coating, aluminum

foil varnish, etc. Also can be used for making ink, adhesive (metal with metal, metal with PVC/PET), heat-seal packing paint (medicine packing,

cigarette packing), glue for vitamine C packing, etc. It is complying with the standard of food & medical contact. |

Specification:

Appearance: white powder

composition: 85%±3% vinyl chloride; 14%±2% vinyl acetate; 1%±0.2% maleic acid; K Value: 50 ± 2

Fineness (passing 4omesh): 100%

Apparent density: 0.45 — 0.5

Volatile matter: 1% max

Black point: 10 numbers / 100g max

Solubility (in 20% methyl ethyl ketone toluene solution): colorless & transparent

Packing:

25kg per bag.

Storage & transportation:

Store in dry & ventilated warehouse. Don't store it in open air. Prevent sunshine & moisture.

Avoid rain during transportation. It is not dangerous cargo.

|

|

|

|

HYDROXYL MODIFIED TERNARY COPOLYMER RESIN AH-VAGH

Equivalent: "VAGH" ex Union Carbon

Property:

It is hydroxyl modified ternary copolymer of vinyl chloride, vinyl acetate & vinyl alcohol. Molecular weight: 27000. It is soluble in correspondingly

strong solvent & thinner composition, for example, 50% ketone & 50% aromatic hydrocarbon, producing 20% (solid count) resin solution.

VAH has very good mutual solubility with other filmforming matter, for example, alkyd resin, polyurethane elastomer, carbimide acetate resin,

epoxy polymer, melamine resin, urea - formaldehyde resin, etc. It is often used with other filmforming matter, to improve paint performance,

reinforce the adhesive power, flexibility, tenacity, hardness & chemical resistance of paint.

|

Specification:

Appearance: white powder

composition: 90%±3% vinyl

chloride, 4%±1% vinyl acetate,

6%±0.2% vinyl alcohol K Value

(VN): 58 ± 2

Fineness (passing 4omesh):

100%

Apparent density: 0.45 — 0.5

Volatile matter: 1% max

Black point: 10 numbers /

l00g max

Solubility (in 20% methyl ethyl

ketone toluene solution):

colorless & transparent

Typical Use: 25kg per bag

Storage & transportation:

Store in dry & ventilated warehouse. Don't store it in open air. Prevent sunshine & moisture. Avoid rain during transportation. It is

not dangerous cargo.

|

|

ALDEHYDE RESIN

Characteristics:

Polyaldehyde is a kind of hard resin with light colour, yellowing resistance and low

viscosity. It's non-toxic and soluble in most solvents used in coating. And it can be mixed

and solved with many basic resins used in coating. So it can raise coating's properties

greatly, such as glossiness. buildines. hardness of surface layer and flexibility. It has good

wetting with pigments. Polyaldehyde resin can be used in coating with high solid content.

( Properties and uses are similar to Laropal A 81.) |

|

|

Main products and Quality:

| model |

HM-100 |

HM-80 |

standards |

| softening point (°C) |

95-105 |

80-95 |

GB/T12007.6-1989 |

| Hydroxyl value mgKOH/g) |

˜ 40 |

˜ 40 |

GB/T7581-1985 |

| acid value(mgKOH/g) |

≤4 |

≤4 |

GB1668-1995 |

| saponificatin value(mgKOH/g) |

˜ 50 |

˜ 50 |

DIN53401 |

| iodometric scale |

≤4 |

≤4 |

DIN616 |

Application:

• Coating: coatings for furniture. automobile and motorcycle etc. , air -drying paint. non air-drying paint, hot-melt coating.

• Colour paste: ideal interlocking material, can shorten paste mill time greatly.

Appearance and Package:

Colourless or yellowish powder, paper-plastics composite bag, net weight: 25kg.

Storage and transportation:

Stored at dry and ventilated condition, be far away from flame. The shelf life is one year. Take shelter from light and rain during transportation.

|

|

|

|

POLYKETONE RESIN

Characteristics:

Polyketone resin is a kind of hard resin with high photostability. It's non-toxic and light-coloured.

And it's soluble in any solvent used in coating industry except for fatty alkane and water. It also

can be mixed and solved with many resins used in paint and ink. So it can raise paint's and ink's

properties greatly, such as glossiness, adhesion, pigment wettability, hardness of surface layer and

system's solid content. Furthermore, it can reduce system's viscosity. When it's applied in adhesives,

it can enhance their first adhesivity, especially it's durable adhesivity. |

|

Main Products and Quality:

| Model |

AH-120 |

A-110 |

AHM-120 |

AHR120 |

A-100 |

HMR-80 |

| softening point |

≥115 |

100-120 |

≥120 |

≥115 |

90-100 |

75-95 |

| (˚C) |

| hydroxy value |

40-90 |

70-130 |

150-230 |

210-280 |

70-130 |

40-100 |

| (mgKOH/g) |

| acid value mgKOH/g) |

≤0.1 |

≤0.1 |

≤0.5 |

≤0.5 |

≤0.1 |

≤0.1 |

| Colourity |

≤10 |

≤3 |

≤18 |

≤3 |

≤3 |

≤3 |

| (40%2-propanol solution |

Application:

• ink: printing ink, gold blocking ink, anti-forge ink and flexible relief ink etc.

• paint: nitro-paint, acrylic resin paint, chlorinated rubber paint, amino resin paint, polyester paint. (topcoat primer of automobile and

motorcycle, primer of furniture, fancy paint etc.

• overprinting varnish: overprinting varnish for paper, cigarette bag etc.

• adhesive: heat-melting type pressure sensitive adhesive, solvent sensitive adhesive.

Appearance and Package:

Colourless or yellowish powder, paper-plastics composite bag, net weight: 25kg.

Storage and transportation:

Stored at dry and ventilated condition, be far away from flame. The shelf life is one year. Take shelter from light and rain during transportation.

|

|

|

MALEIC ACID RESIN ALCOHOL SOLUBLE

Introduction:

It is made from maleic modified resins through esterification with polyalcohol.

Features:

It cans soluble in alcoholic solvents; fast drying and high gloss. It also can be used for water- based inks.

|

|

Specifications:

| (Items) |

HM-110 |

HM-130 |

HM-150 |

| Color(Gardner)(50%Benzene solution) |

≤8 |

≤8 |

≤8 |

| Softening point(R&B) |

110±5°C |

130±5°C |

150±5°C |

| Acid value (mgKOH/g) |

190±10 |

180±10 |

170±10 |

Typical Use:

For alcohol soluble intaglio printing inks, gloss oil polish and water-base inks.

Forms and Packaging:

* Bag: beads or flake, kraft paper bag or plastic woven bag, 25kgs net each bag.

* Packing specified by customers.

|

|

SOLID ACRYLIC RESIN

Solubility:

It can be soluble in alcohols, esters, Ketones and Aromatics at normal temperature.

Characters:

A. Good gloss

B. Good abrasion resistance

C. Applied in coatings and inks with strict requirement of environment.

Application:

For Solid Acrylic Resin HM-66/HM-725:

1. Soft plastic paint.

2. Plastic printing ink

3. Container paint.

4. Industry paint.

For Solid Acrylic Resin Alcohol Soluble HM-53/HM-396:

1. Alcohol soluble inks

2. Alcohol soluble coatings

3. Alcohol soluble adhesives

Packing:

25kgs net per bag, l2500kgs/1x20'gp with pallet.

Storage:

Should be stored in dry, aeration area, avoiding the wet. The valid store period is two years. |

|

|

Specification:

ITEMS / TYPES

|

Thermoplastic

HM-66 |

Thermoplastic

HM-725 |

HM-53

(ALCOHOL SOLUBLE) |

HM-396 (ALCOHOL SOLUBLE) |

| Appearance |

White Powder |

White granular |

White granular |

White granular |

| Solid Content (%) |

100 |

100 |

100 |

100 |

| Softening Point (°C) |

130-150 |

150-160 |

112 |

108 |

| Acid Value, mgKOH/g |

3-6 |

5-8 |

5.96 |

4.29 |

| Tg(°C) |

50 |

61 |

53 |

39.69 |

| Viscosity mpa.s (40% in ethanol) |

mpa.s (25°C) (Viscosity)

2000-4000 (51% in toluene) |

300-400 |

430 |

150 |

|

|

|

|

CHLORINATED RUBBER RESIN

-WATER PHASE METHOD

Properties:

Chlorinated Rubber Resin is a kind of environment friendly resin. The chlorination process carries on in the aqueous phase, does not use the

organic solvent completely, it has avoided the disadvantage that caused by using the CCI4 method chlorination a kind of method that adopted by

some plants recently), and the latter has not permitted by the Environmental Protection Law. It has the all excellent physical chemical properties

of the solvent method chlorinated rubber, is its ideal substitution product. Its development has successfully tilled the domestic blank of aqueous

phase chlorinated rubber's production technology.

Chlorinated Rubber Resin is a kind of thermoplastic resin of high hardness and powdery. It has good weathering resistance, fine adhesion ability,

high chemical stability, excellent saltwater resistance and good ultraviolet resistance. It is readily soluble in organic solvents such as toluene,

xylene, acrylic resin, alkyd and other esters, forming a colorless or yellow transparent solution. When this solution is applied to the surface of

metal , concrete, paper etc, the solvent readily vaporizes at room temperature and forms a layer of transparent, hard and glossy glassiness

film. This thin film can prevent the steam and the oxygen penetration, it shows very high stability to various chemicals (for example acid, alkali,

etc.) has the very high stability to each chemical substance as well. It also protects the basal body, prevents it from corrosion, and also serves

as a top coating for decorative purposes. In addition, because this product has the very high chlorinity, therefore has the tine flame resistance.

|

Applications:

Chlorinated Rubber Resin is widely used in the oil paint, coating, printing ink and the binder. Its price

is lower than of chlorinated rubber produced by using the solvent method, so it is a kind of functional

resin with good ratio of ability and price.

|

|

|

Specification:

| Items / Specifiation |

CR-5 |

CR-10 |

CR-20 |

CR-40 |

| Content of chlorde (%) ≤ |

65 |

65 |

65 |

65 |

| Viscosity (s)20wt% xylene solvent 25˚C) |

4-8 |

8-13 |

13-18 |

30-50 |

| MAX solubility (w/w) % |

60 |

150-160 |

112 |

108 |

| Volatility (%)≤ |

0.5 |

5-8 |

5-96 |

4.29 |

| Volatility (%)≤ |

0.4 |

61 |

53 |

39.69 |

|

|

ZIRCONIUM SILICATE BEADS

Type: S-Zr65A (grinding grade)

S-Zr65B (blasting grade)

|

|

|

Applications:

This product is specially researched and prepared for more than four years by our technical department ,using the sintering process with

introducing advanced equipments from abroad. The property and technical specifications of this product reach the international advanced level.

It is mainly applied in the grinding and dispersion of calcium carbonate, kaolin, zirconia, titanium dioxide, dyestuffs, printing ink, coating, and

can also be used in the surface treatment of the metals, such as polishing.

Specifications:

Composition: Zr02: 65%, Si02: 35%

Density: > 4.0g/cm3

Packing density: 2.5g/cm3

Hardness: MOH'S scale 7.2

Wear Rate: reach advanced level in the world

Size: Ø0-0.063, Ø0.063-0.125, Ø0.125-0.25, Ø0.25-0.425, Ø0.4-0.6, Ø0.6-0.8, Ø0.8- 1.0, Ø1.0-1.2, Ø1.2-1.4, Ø1.4-

1.7, Ø1.5-2.0, Ø2.0-2.5... or any customize sizes.

Product Features:

The beads have smooth and grinding surface and high density, so they don't have the appearance of being hollow, anomalistic, or

with small beads on the surface

Excellent tenacity, this advantage makes the bead keep fine in high rotation speed; low friction coefficient makes the lower abrasion

to the equipment

High density makes higher mill efficiency

|

|

HOLLOW GLASS MICROSPHERES |

Product Introduction

High-performance hollow glass microsphere is a kind of ultra- lightweight inorganic non-metallic material (powder) with hollow structure

(microsphere), and it is a versatile and high-performance new lightweight material developed in

recent years. It will be the new composite (mainstream)materials at twenty-first century. Its true

density is O.20-0.60g/cm3 with 2-l2Oμm in diameter. It owns features with light weight, large

bulky, low thermal conductivity, high compressive strength, smoothly mobility etc.

Applications:

Its applications are in the fields of Thermal insulation coating, putty, plastic casting polyester, FRP

,SMC, synthetic foam, adhesives, printed circuit board substrate, RTM, bowling, fan blades, & caulking

materials, emulsion explosives, golf, sealant, pipeline insulation materials, artificial marble, PVC foam,

low density oil drilling, light cement, and other deep-sea buoy etc. |

|

Product Series specification:

| Product |

Materials |

Color |

True Density g/cm3 |

Pressure

Resistance

Mpa |

Particle Size μm |

Floating

Rate |

Melting

Point |

PH |

| 10th% |

50th% |

90th% |

| AH-20 |

Soda Lime Borosilicate Glass |

white |

0.20 |

3 |

32 |

68 |

106 |

>96% |

625˚C |

8-9.5 |

| AH-25 |

Soda Lime Borosilicate Glass |

white |

0.25 |

5 |

30 |

65 |

100 |

>96% |

625˚C |

8-9.5 |

| AH-32 |

Soda Lime Borosilicate Glass |

white |

0.32 |

11 |

30 |

56 |

74 |

>96% |

625˚C |

8-9.5 |

| AH-40 |

Soda Lime Borosilicate Glass |

white |

0.40 |

20 |

20 |

45 |

70 |

>96% |

625˚C |

8-9.5 |

| AH-46 |

Soda Lime Borosilicate Glass |

white |

0.46 |

30 |

22 |

45 |

65 |

>96% |

625˚C |

8-9.5 |

| AH-60 |

Soda Lime Borosilicate Glass |

white |

0.61 |

50 |

18 |

40 |

60 |

>96% |

625˚C |

8-9.5 |

Packing specification

| Currently packing specification |

Product Series |

| Packing Specification mm |

AH-25 |

AH-32 |

AH-40 |

AH-46 |

AH-60 |

| Paper box400*400*400 |

9KG |

12KG |

15KG |

17KG |

22KG |

| Paper box400*400*520 |

12.5KG |

15KG |

20KG |

24KG |

30KG |

| Paper box650*650*800 |

50KG |

64KG |

80KG |

93KG |

120KG |

| PE Knitted Bag |

10KG |

12.5KG |

15KG |

15KG |

20KG |

|

|

|

|

|

|